Making Koji

Japan Sake and Shochu Makers Association | JSS

The process of making shochu involves fermentation and distillation. Regardless of the selected base ingredient, the basic method of shochu production remains the same.

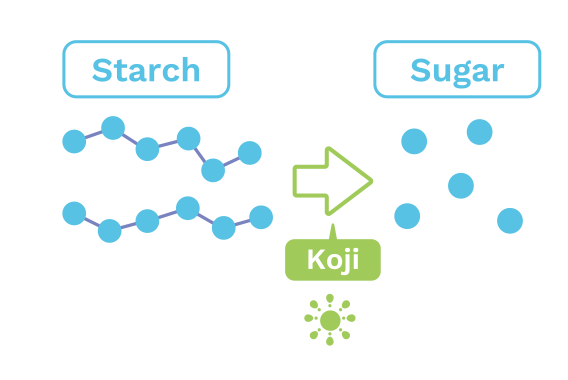

Koji provides the enzymes required to break down starch into sugar. It also produces citric acid that prevents the fermenting mash from spoilage.

Duration: 40 hours

Steam polished rice.

Cool steamed rice and sprinkle koji spores.

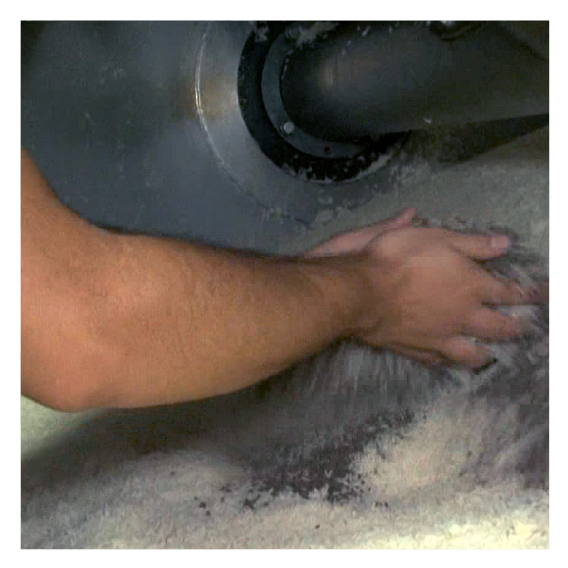

Adjust temperature and humidity to cultivate koji mold on rice.

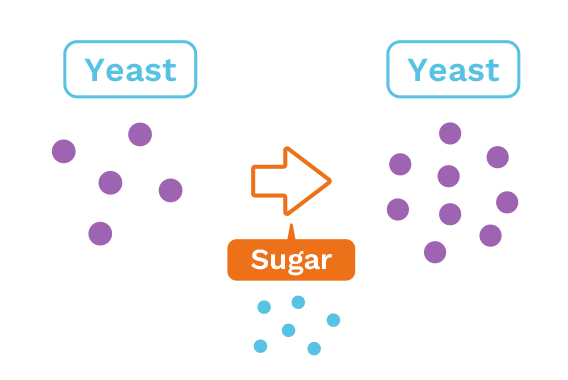

The first moromi is the starter mash made of koji, water, and yeast. This is where a sufficient amount of yeast is cultivated.

Duration: 3 to 8 days

Koji enzymes convert starch into sugar.

Yeast uses the sugar to multiply.

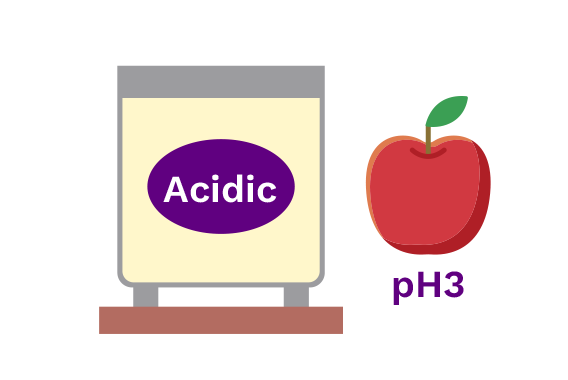

Koji produces citric acid and makes the mash acidic to around pH3 (the same as an apple).

The second moromi is where the main fermentation process takes place. By the end of the fermentation, it contains about 14-19% of alcohol.

Duration: 2 weeks

Steam base ingredient.

Mix the base ingredient with the first moromi and water.

Let it ferment.

Alcohol and flavor components are extracted from the second moromi. The distillate usually contains around 37-45% alcohol. Sweet potato-based shochu acquires slightly less alcohol content compared to cereal-based shochu, at around 37-40%. For more information about distillation, read here.

After distillation, shochu makers filter the shochu and store it to develop a smoother taste. For more information about the aging process, read here.

Most shochu is diluted with water to bring down the alcohol content to 20 to 25% before bottling.